Safe Fume Hood Procedures

Lab fume hoods are a critical piece of any safe laboratory operation and are often the primary control device when it comes to keeping laboratory personnel safe when working with toxic or flammable chemicals. Understanding and following the correct operational procedures is an absolute must for anyone using a fume hood.

For starters it is important to understand when to use fume hoods or when an alternative system, such as a biosafety cabinet, is needed. Below are some scenarios of when a fume hood should be used:

- When carrying out procedures where there is a buildup of high pressure gases or the possibility of an explosion.

- Working with chemicals or compounds that have strong odors.

- Procedures or chemicals that could cause inhalation hazards.

- Working with radioactive materials or toxic powders.

- Anytime there are chemicals that could create a fire hazard.

- When using chemicals with an NFPA rating of 3 or 4.

Below you will find a link to the iQ Labs Fume Hood Guide where you will find explanations for the basic components that make up a traditional fume hood in case you are not familiar. Having a general understanding of each of the main components that make up a hood is a good starting point for safe operation.

iQ Labs Guide to Laboratory Fume Hoods

Sash Operation

One of the most important aspects when it comes to the proper usage of a fume hood is understanding the importance of the sash. The sash is the main protective barrier that should always be kept between the operator and the procedure occurring inside the hood.

Why should you keep the fume hood sash closed? Sash glass is typically made with laminated layers similar to those in the windshield of a car and will act as a shield in the event of an explosion as well as protecting the user from chemical splatter. In the event of a fire, the sash also acts as the primary containment mechanism.

The sash position has a major impact on the performance and air draw of the fume hood. A sash that is too far open will reduce the face velocity of air and could cause toxic fumes or gases to escape, putting the user at risk of inhalation. Most hoods are tested for face velocity at varying sash heights but it should be known that the hoods face velocity will be directly affected by sash position. A good rule of thumb when it comes to sash position is the lower the better. Many fume hood manufacturers equip their hoods with sash stops around 18″ above the airfoil to prevent users from inadvertently opening the sash too far.

Baffle System

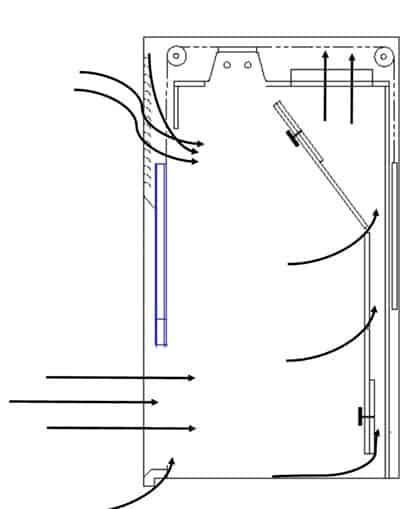

Located at the rear of the hood, the baffle system is a set of partitions, typically made from the same material as the interior lining of the hood, that direct airflow. Depending on the brand of fume hood, this system could be a single piece system with slotted openings in the liner board or it could consist of a few different panels spaced out to allow for the movement of air. Below is an example of a baffle system which also shows moveable dampers that can be positioned based on the types of gases or fumes being created.

Typically the baffle system sits 2-3 inches from the backwall of the hood. It is important that nothing blocks the baffle openings and that any equipment placed in the hood is elevated a minimum of two inches to allow for airflow along the surface of the fume hood deck. Paper and other light objects should be used with caution, as they could get drawn up into the baffle system causing airflow blockages and decreased performance of the fume hood.

Fume Hood Face Velocity and The Airfoil

The face velocity of the hood is the baseline testing measure for fume hood certification. A minimum of 80-100 feet per minute (FPM) depending on the hood type is the minimum acceptable velocity for meeting the ASHRAE 110 standard for safe operation. Some hoods are considered “high efficiency” and operate at a lower face velocity (as low as 60 FPM) which helps conserve energy.

The airfoil located at the front of the hood is a critical component of creating smooth laminar airflow and directing the air inside. When the sash is closed, air is brought into the hood through the under-side of the airfoil as well as through a bypass at the top of the front panel and sash. Similar to the baffle system, avoid blocking the airfoil with equipment, chemicals, etc.

It is important to frequently check the airflow of the hood and log your findings for future reference. This can be done using an anemometer or using a visual aid such as a smoke machine or dry ice. There should be no smoke escaping the hood and the movement of the air should be smooth and consistent. Note any turbulent airflow or any anemometer readings that are outside the normal range for the specific fume hood that you operate.

Other considerations

It is important to read the operating manual for your specific hood as procedures can differ slightly from one model to the next. Below are some additional considerations for the safe operation of a fume hood:

- Do not store chemicals or other materials in the hood.

- Keep materials needed for procedure a minimum of 6 inches from the front of the hood to avoid spills.

- Wear eye protection.

- Never put your head inside the plane of the sash.

- When working with explosive chemicals, use a blast shield for additional protection.

If you have any questions regarding fume hood operation or are curious about what equipment would be the right fit for your lab, contact us at sales@iq-laboratory.com or call us direct at 231-767-1301.